Unlocking Efficiency: How AWS IoT Powers Real-Time Monitoring & Predictive Maintenance in Manufacturing

In today’s competitive manufacturing landscape, operational efficiency and minimizing downtime are vital to success. To stay ahead, manufacturers are increasingly adopting Industry 4.0 technologies like the Internet of Things (IoT). AWS IoT enables manufacturers to implement real-time monitoring and predictive maintenance, reducing unplanned downtime, improving operational efficiency, and cutting costs.

In this blog, we’ll explore how AWS IoT supports real-time monitoring and predictive maintenance, along with practical use cases and best practices for deploying these solutions in manufacturing.

Table of Contents

- How AWS IoT Enables Real-Time Monitoring

- Predictive Maintenance with AWS IoT: How It Works

- Case Study: Real-Time Monitoring and Predictive Maintenance in Action

- Practical Use Cases of AWS IoT in Manufacturing

- Best Practices for Implementing AWS IoT in Manufacturing

- Key AWS IoT Services for Manufacturers

- The Value of AWS IoT for Your Manufacturing Operations

- Get Your Free Assessment with CloudJournee

How AWS IoT Enables Real-Time Monitoring

Real-time monitoring is essential for manufacturers to enhance operational efficiency and prevent equipment failures. With AWS IoT services, manufacturers can monitor the health and performance of machinery in real time, capturing critical data from sensors and taking immediate action when needed.

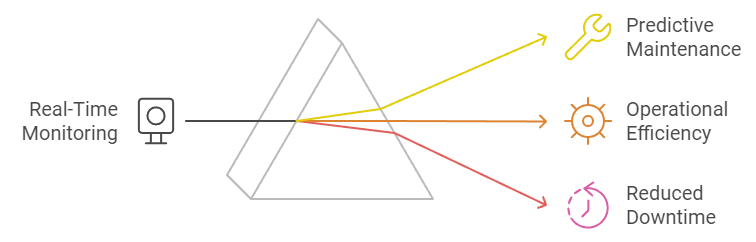

Key AWS IoT Features for Real-Time Monitoring:

These services offer manufacturers a comprehensive solution to gain real-time insights into machine health and performance, allowing swift responses to potential issues.

Predictive Maintenance with AWS IoT: How It Works

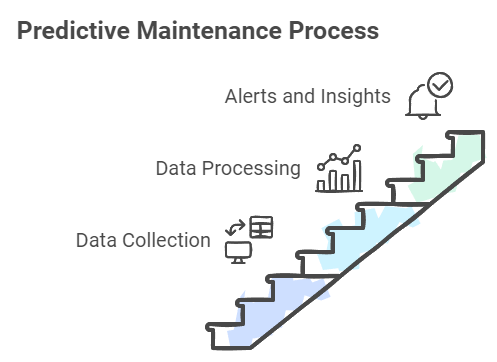

Predictive maintenance leverages historical and real-time data to forecast equipment failures, allowing manufacturers to avoid costly breakdowns. AWS IoT, combined with machine learning (ML) and analytics, enables manufacturers to predict failures, ensuring maintenance is performed precisely when needed.

How Predictive Maintenance Works:

This proactive approach minimizes disruptions, extends machine lifespan, and optimizes maintenance schedules.

Case Study: Real-Time Monitoring and Predictive Maintenance in Action

Industrial Equipment Manufacturer Case Study

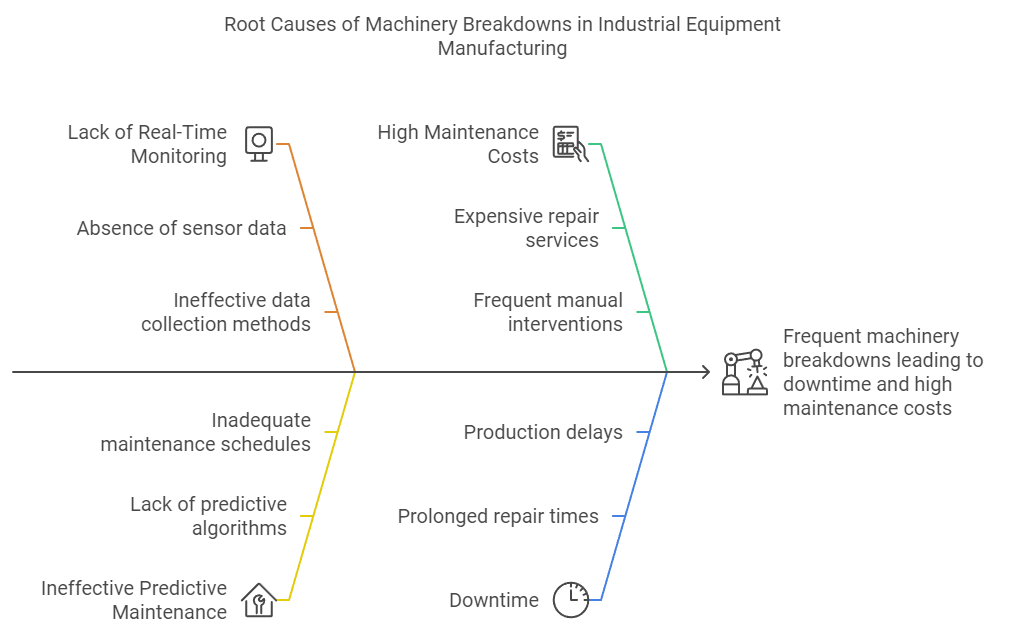

Challenge: A large industrial equipment manufacturer faced frequent machinery breakdowns, leading to significant downtime and high maintenance costs.

Solution: The company implemented AWS IoT Core, AWS IoT SiteWise, and Amazon SageMaker to collect real-time sensor data and predict machine failures using ML algorithms. The system allowed for continuous monitoring and provided predictive maintenance alerts.

Results:

This real-world example highlights how AWS IoT can transform manufacturing operations by reducing downtime and increasing overall efficiency.

Practical Use Cases of AWS IoT in Manufacturing

Let’s explore a few practical use cases that demonstrate the power of AWS IoT for real-time monitoring and predictive maintenance.

Use Case 1: Smart Factory Automation

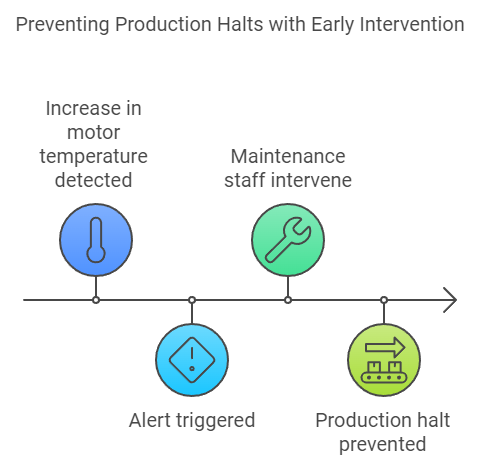

In smart factories, AWS IoT services enable fully automated production lines. Sensors track parameters like temperature and vibration, while AWS IoT Greengrass processes data at the edge, sending real-time alerts for anomalies.

Example: A food processing plant uses AWS IoT Core to monitor its packaging line. When the system detects a slight increase in motor temperature, it triggers an alert, enabling early intervention and avoiding costly downtime.

Use Case 2: Predictive Maintenance in Automotive Manufacturing

Automotive manufacturing relies on predictive maintenance to ensure the uptime of critical machinery. AWS IoT SiteWise collects data from assembly-line robots, while Amazon SageMaker predicts when parts will need replacement.

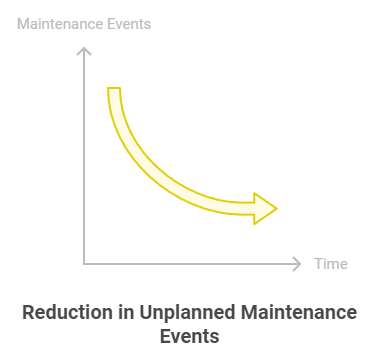

Example: A car manufacturer reduced unplanned maintenance by 40% using AWS IoT-based predictive maintenance. The system identified early signs of motor wear in welding robots, allowing replacements during scheduled downtime.

Use Case 3: Reducing Downtime in Heavy Machinery

In industries like mining and oil & gas, AWS IoT enables real-time monitoring of expensive, hard-to-repair heavy machinery. ML algorithms predict failures, allowing for preventive maintenance.

Example: A mining company reduced downtime by 35% and saved millions in repairs by using AWS IoT to monitor excavators, fixing minor issues before they became critical.

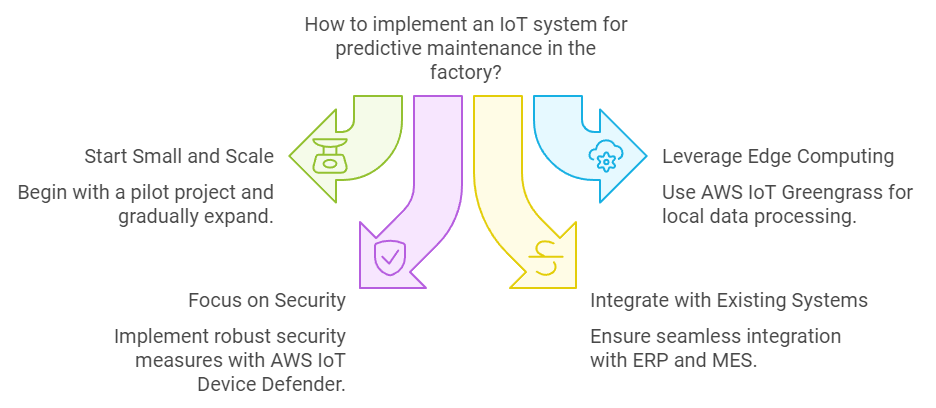

Best Practices for Implementing AWS IoT in Manufacturing

To maximize the benefits of AWS IoT, manufacturers should adopt the following best practices for a successful implementation:

- 1

Start Small and Scale: Begin with a pilot project, then expand across the factory as confidence grows.

- 2Leverage Edge Computing: Use AWS IoT Greengrass to process data locally, minimizing latency for critical decisions.

- 3Focus on Security: Implement robust security measures like AWS IoT Device Defender to safeguard IoT devices.

- 4

Integrate with Existing Systems: Ensure seamless integration with ERP and MES for unified operational management.

- 5

Utilize Machine Learning Models: Continuously improve predictive maintenance models with Amazon SageMaker to enhance failure prediction accuracy.

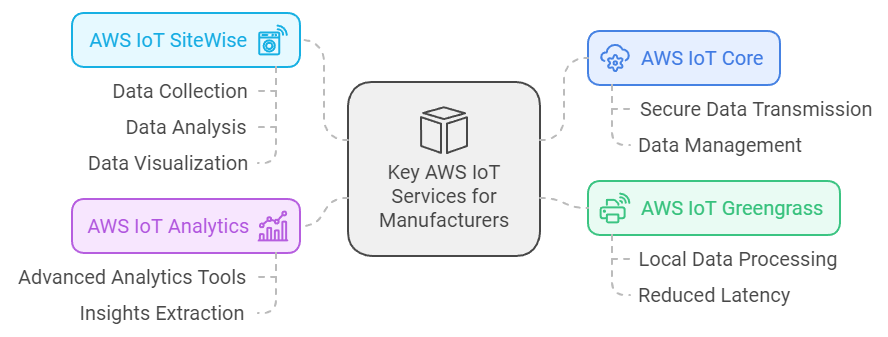

Key AWS IoT Services for Manufacturers

AWS offers a robust suite of services to drive real-time monitoring and predictive maintenance in manufacturing:

Key AWS IoT Services:

The Value of AWS IoT for Your Manufacturing Operations

By leveraging AWS IoT, manufacturers can unlock significant operational and financial value. Here’s how adopting real-time monitoring and predictive maintenance can directly benefit your business:

Reduced Unplanned Downtime

With AWS IoT’s real-time monitoring and predictive maintenance, manufacturers can identify potential issues before they result in machine failure. This proactive approach significantly reduces unplanned downtime, ensuring production lines continue running smoothly. Fewer breakdowns translate into uninterrupted production, higher output, and meeting deadlines without delays.

Cost Savings on Maintenance

Traditional maintenance schedules often rely on routine checks that don’t always reflect the true condition of machinery. AWS IoT enables predictive maintenance, where repairs are only performed when needed. This eliminates unnecessary maintenance tasks, extends the lifespan of equipment, and reduces labor costs. You only repair what truly needs fixing, saving on maintenance costs while avoiding expensive emergency repairs.

Increased Equipment Efficiency and Lifespan

Real-time monitoring with AWS IoT ensures that machines operate at optimal efficiency by constantly tracking performance metrics such as temperature, vibration, and motor speeds. This not only keeps equipment running smoothly but also reduces wear and tear, increasing the overall lifespan of your machinery. Longer-lasting equipment leads to fewer capital expenditures and lower total cost of ownership.

Enhanced Decision-Making with Data-Driven Insights

AWS IoT collects, analyzes, and visualizes critical data in real-time, allowing your teams to make informed decisions. From knowing when to schedule maintenance to identifying production bottlenecks, data-driven insights empower you to optimize manufacturing operations for greater productivity and reduced waste.

Improved Safety and Compliance

IoT-enabled monitoring can also help you ensure that machinery is operating within safety and compliance guidelines. Real-time alerts can detect unsafe conditions early, allowing for timely interventions that prevent accidents or non-compliance incidents. This not only safeguards your workforce but also ensures adherence to industry regulations, reducing legal and financial risks.

Scalability and Flexibility

AWS IoT solutions are scalable, allowing you to start with a single production line and expand as needed. Whether you operate a small manufacturing plant or a large industrial facility, AWS IoT grows with your business, enabling you to continually improve and scale your operations without significant upfront investment.

Competitive Advantage

By adopting AWS IoT for predictive maintenance and real-time monitoring, your business can gain a competitive edge. Reduced downtime, lower maintenance costs, improved productivity, and better resource utilization translate into higher profitability. Being at the forefront of smart manufacturing technology allows you to stay ahead of competitors who are slower to adopt IoT solutions.

Key Takeaway:

AWS IoT provides tangible value by improving operational efficiency, lowering costs, and enhancing equipment reliability. For manufacturers, this means increased profitability, higher productivity, and long-term sustainability. By embracing AWS IoT solutions, you’re not just upgrading your technology; you’re transforming your entire business to thrive in the Industry 4.0 era.

Get Your Free Assessment with CloudJournee

Ready to revolutionize your manufacturing with AWS IoT? CloudJournee offers a Free Assessment and Consulting Call to evaluate your current operations and recommend how AWS IoT can enhance equipment monitoring and predictive maintenance strategies.