Enhancing Supply Chain Resilience in Manufacturing with AWS Cloud

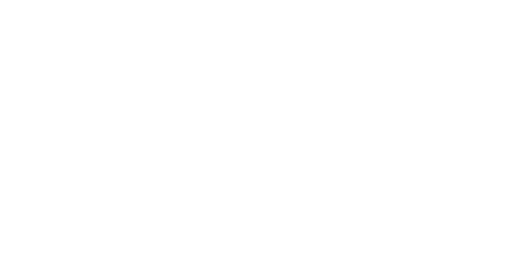

In today’s rapidly evolving manufacturing landscape, supply chain resilience has become a critical factor in maintaining operational efficiency and responding to unforeseen disruptions. Amazon Web Services (AWS) offers a robust suite of cloud services that can significantly enhance supply chain management systems, making them more resilient, scalable, and responsive to challenges. This blog post will explore how AWS services such as AWS Supply Chain, Lambda, and S3 can be leveraged to create a robust supply chain management system for manufacturers.

Technical Know-How: Understanding AWS Services for Supply Chain Management

AWS Supply Chain

AWS Supply Chain is a cloud-based application that provides real-time visibility and actionable insights to help organizations mitigate supply chain risks and lower costs. It uses machine learning to analyze data from various sources, including internal ERP systems, supplier networks, and external data feeds.

Key features:

- Supply chain visualization

- Risk assessment and mitigation recommendations

- Demand forecasting

- Inventory optimization

AWS Lambda

AWS Lambda is a serverless compute service that runs code in response to events and automatically manages the underlying compute resources. In a supply chain context, Lambda can be used to:

- Process and analyze incoming supply chain data

- Trigger alerts and notifications for potential disruptions

- Automate inventory reordering processes

- Execute complex calculations for demand forecasting

Amazon S3 (Simple Storage Service)

Amazon S3 is an object storage service offering industry-leading scalability, data availability, security, and performance. In supply chain management, S3 can be used to:

- Store and manage large volumes of supply chain data

- Host static websites for supplier portals

- Backup and archive critical supply chain documents

- Enable data lakes for advanced analytics

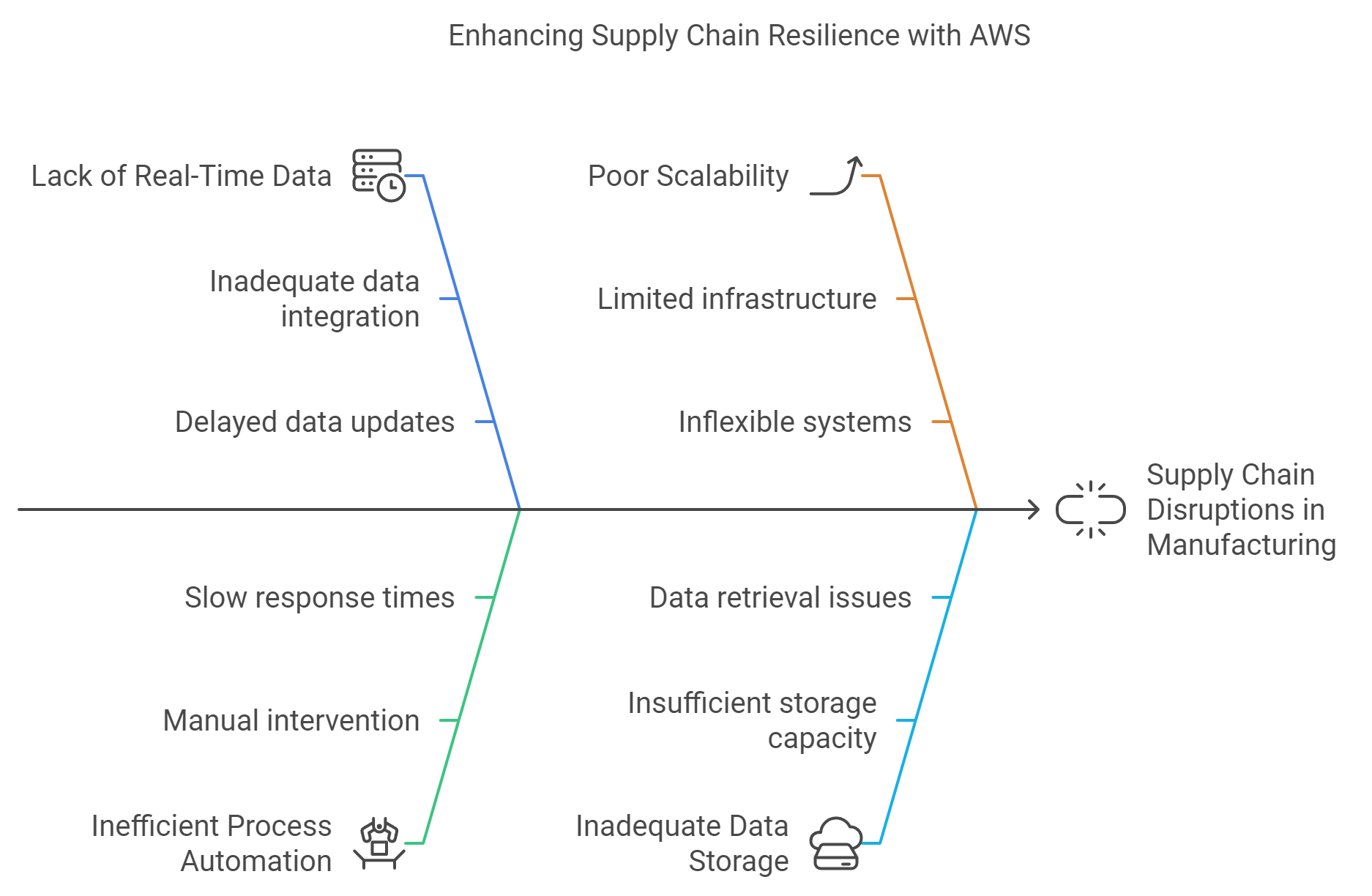

How-To: Implementing a Resilient Supply Chain System with AWS

Step1: Set up AWS Supply Chain

Step2: Set up AWS Supply Chain

Example function: Inventory threshold monitoring

Step3: Set up S3 Buckets for Data Storage

Step4: Integrate Services

Practical Use Case: Global Automotive Manufacturer

A leading automotive manufacturer faced challenges with supply chain disruptions due to global events and needed to enhance their resilience. They implemented an AWS-based solution with the following components:

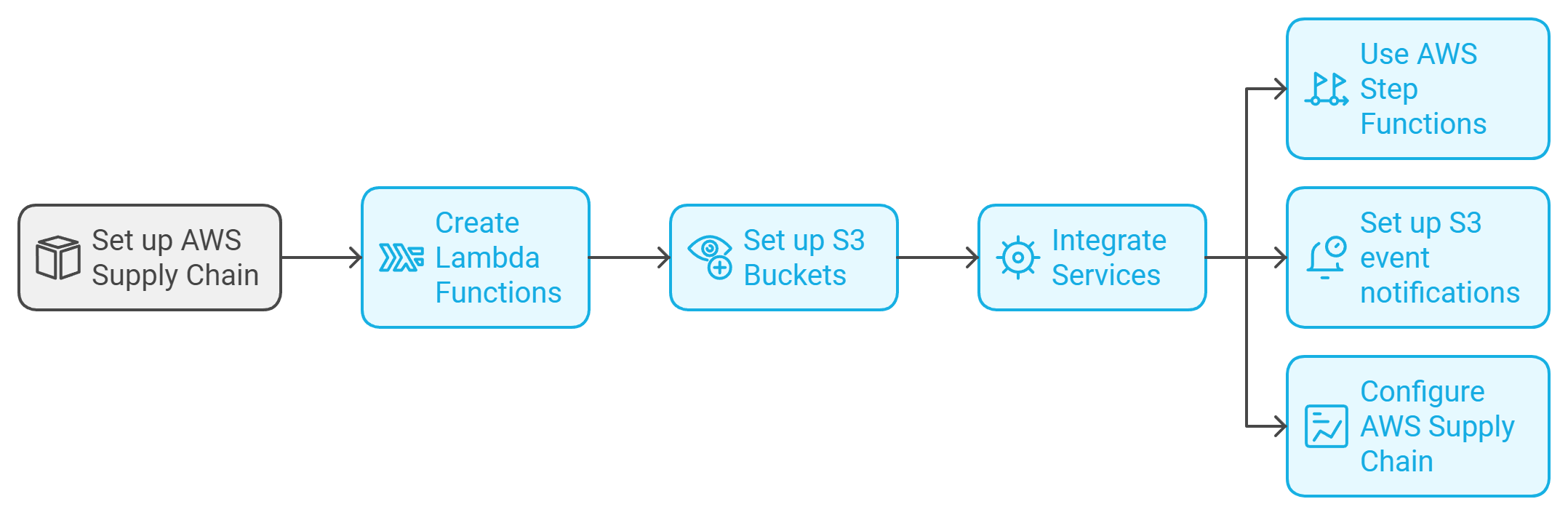

Results:

- 30% reduction in supply chain disruptions

- 25% improvement in inventory turnover

- 15% increase in on-time deliveries

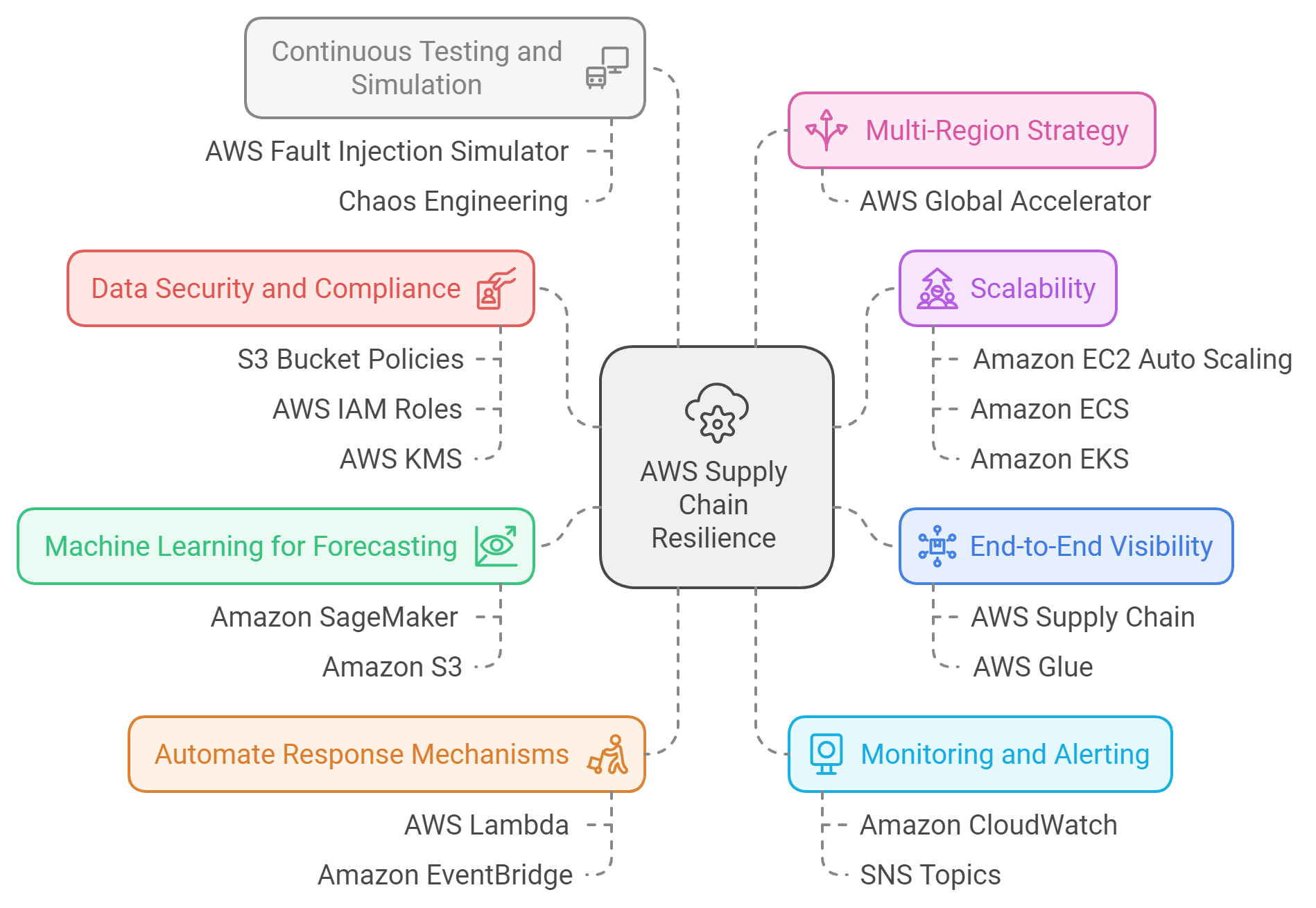

Best Practices for Supply Chain Resilience with AWS

By following these best practices and leveraging AWS services, manufacturers can significantly enhance their supply chain resilience, enabling them to respond effectively to disruptions and maintain operational efficiency in an ever-changing global landscape.

Conclusion

Enhancing supply chain resilience is crucial for manufacturing companies to thrive in today’s dynamic business environment. AWS provides a comprehensive suite of services that enable manufacturers to build robust, scalable, and responsive supply chain management systems. By leveraging AWS Supply Chain, Lambda, S3, and other AWS services, companies can gain real-time visibility, automate processes, and make data-driven decisions to mitigate risks and optimize their supply chain operations.

Are you ready to transform your supply chain and enhance its resilience? CloudJournee offers a free AWS Assessment and Consulting Call to help you get started on your journey to a more resilient and efficient supply chain. Our team of AWS-certified experts will analyze your current infrastructure, identify opportunities for improvement, and provide tailored recommendations to leverage AWS services for your specific needs.

Don’t let supply chain disruptions hold your business back. Take the first step towards a more resilient future with CloudJournee and AWS.